Craftsmanship in Action: A Visit to The Benbow Group

As part of my role at the NAS, I recently had the pleasure of visiting Benbow Group – an extraordinary company quietly delivering some of the most precise, high-quality interior fit-outs for luxury brands, museums, and blue-chip corporate clients across the UK.

From the moment I stepped into their 50,000 sq ft workshop, I was struck by the level of detail, care, and pride that permeates everything they do. Whether it’s producing bespoke display cases for luxury watchmakers or executing complex refurbishments for high-end retail spaces, the Benbow team is full of experts who are masters at their crafts.

Where Craft Meets Precision

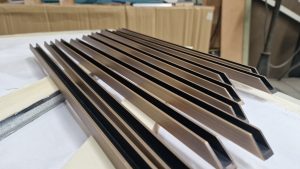

What sets Benbow apart is their dual commitment to traditional craftsmanship and modern precision. In their Specialist Joinery division, skilled craftspeople use cutting-edge CNC machinery to produce stunning, bespoke pieces. I saw first-hand how their veneering, lacquering, and edge-banding operations turn raw materials into statement pieces worthy of any luxury interior.

It’s a place where young apprentices and experienced technicians work side by side – ensuring that craftsmanship is not only preserved but constantly refined for the demands of today’s fast-paced, high-expectation projects.

Metalwork with a Signature Finish

Their Architectural Metalwork division is equally impressive. From CNC milling and welding to bronzing and polishing, this department delivers the kind of bespoke solutions that would be at home in any high-profile hospitality or retail space. As with their joinery work, the focus is always on precision, durability, and finish – an ethos that’s embedded in every part of their workflow.

A Reputation Built Over Six Decades

Over 60 years in the making, Benbow’s reputation is not accidental – it’s the result of consistent delivery, rigorous quality control, and a clear understanding of what prestige clients demand. What’s more, they carry out the vast majority of their work in-house, which means tighter control over quality and timeline, and fewer compromises.

Their role as either principal contractor or a specialist sub-contractor gives them the flexibility to work across a range of sectors. But whether they’re refurbishing a flagship store or delivering detailed cabinetry for a museum, the standards never slip.

Commitment to the Future

What really stood out during my visit was their focus on continuity – ensuring that skills, standards, and values are passed from one generation to the next. Apprenticeship schemes and trainee technician programs are central to their operation, helping to safeguard the future of skilled craftsmanship in the UK. Benbow’s Director, John Bailey, himself came through the ranks of the business, starting as an apprentice and working his way up to where he is today.

Final Impressions

In an era where fast fabrication often replaces quality craftsmanship, The Benbow Group stands as a beacon of what’s possible when you combine legacy, skill, and modern manufacturing. It’s no surprise that global luxury brands trust them to bring their spaces to life.

Find out more about them here: https://benbowgroup.co.uk/